March 25, 2015

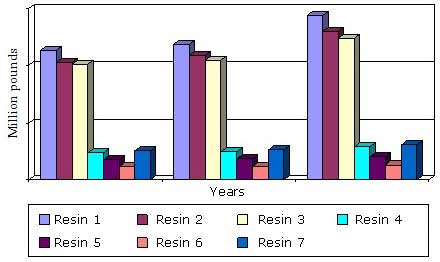

Wellesley, Mass., March 25, 2015 –BCC Research (www.bccresearch.com) reveals in its new report on rigid transparent plastics that the North American transparent plastics market is expected to reach about 5 billion pounds by volume in 2020, reflecting a five-year compound annual growth rate (CAGR) of 3.5%. Polycarbonates, acrylics and polystyrenes, the leading resins in the market, should maintain their aggregate share of 80% of total volume during the forecast period.

Rigid transparent plastics have grown into a significant market that includes many types of polymers. In addition to acrylics and polycarbonates, styrene-based materials and commodity and specialty polymers are available in clear grades. This report covers rigid, clear, non-packaging plastic products that include injection-molded, non-film extrusion, and some thermoformed (including cast sheet) plastics.

Transparent rigid plastics will continue to replace glass in many applications. Glass has excellent optical properties, low price, outstanding UV resistance and excellent chemical and abrasion resistance. However, it is heavy, breaks easily into hazardous slivers and is expensive to form into intricate parts. The limitations of glass outweigh its advantages in many applications as evidenced by the gains of clear plastics in the glass market. Although plastics are more expensive than glass and pose a recycling challenge, their inherent low weight and resistance to breakage have tipped the balance in their favor.

Major applications of these rigid transparent plastics include: medical, electronic, automotive, building and construction (glazing, lighting lenses, signs and displays), housewares, appliances, toys, optical lenses and aircraft transparencies. Many other traditional glass applications such as appliance and business equipment parts, medical and laboratory ware, and many household and industrial items are succumbing to rigid transparent plastics. New polymer options and advanced processing methods are accelerating the shift from glass to transparent plastics in these applications.

“Transparent rigid plastics are not new, but new advances have resulted in products that are not only tougher, but also more chemically resistant,” says BCC Research analyst Mel Schlechter. “These properties were previously a major disadvantage of transparent plastics, but many are now more resistant to heat and abrasion as well.”

Rigid Transparent Plastics provides an in-depth analysis of rigid transparent plastics in terms of current and forecast usage. The report also examines new developments in rigid clear plastics that have expanded usage in existing and new applications.

Editors and reporters who wish to speak with the analyst should contact Steven Cumming at steven.cumming@bccresearch.com.

Rigid Transparent Plastics( PLS003J )

Publish Date: Feb 2015

Data and analysis extracted from this press release must be accompanied by a statement identifying BCC Research LLC as the source and publisher. For media inquiries, email press@bccresearch.com or visit www.bccresearch.com/media to request access to our library of market research.