Next-Generation Connectivity: AiP as the Backbone of 6G Networks

Clear insight into competitor positioning and market share.

Antenna-in-Package, or AiP, is a term used to integrate the antenna (or antenna array) with RF front-end electronics inside a semiconductor package/module. Laying the antenna as a discrete component on a printed circuit board (PCB) is an approach that would be preferable until AiP is available. Still, with an increasing focus on higher frequencies (mmWave and above), shorter wavelengths make such integration not only preferable but often a necessity. AiP minimizes size, reduces losses (feedline, interconnect, etc.), enhances performance (gain, beamforming, polarization control), and ensures compact and scalable packaging at an economical price.

As the world moves toward 6G, the next generation of wireless technology is expected to tap spectrum far beyond today’s 5G millimeter-wave bands — extending into sub-terahertz, D-band and potentially even lower terahertz frequencies. Antenna-in-package, or AiP, is emerging as a critical technology that enables this leap.

6G promises data rates measured in terabits per second, ultra-low latency in the microsecond range and unprecedented reliability. It also faces tight energy constraints while supporting not only communication but also sensing, localization and imaging. To achieve those goals, every inefficiency—whether due to signal loss, misalignment, size or heat — becomes a factor.

Rising Need for High-frequency Performance

For 6G, which runs at higher frequencies of 100 GHz and above, antenna elements become smaller. This enables dense integration and improved beamforming. This trend fits with the overall move toward miniaturization and integration. Devices like smartphones, wearables, IoT sensors, drones and AR/VR systems require compact designs, low power consumption, efficient thermal management and lightweight components.

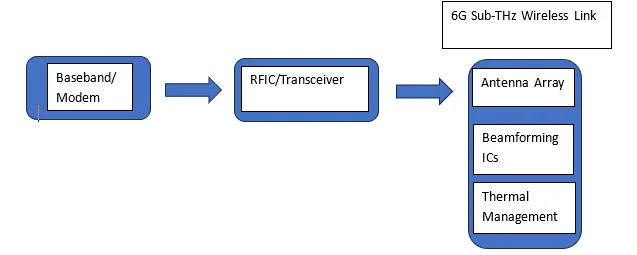

Here is a simple functional block diagram for AiP in a 6G Smartphone

AiP technology meets these needs by simplifying routes, reducing external matching networks and improving alignment tolerances. At such high frequencies, signal losses from feedlines, connectors and PCB traces become significant. AiP provides optimized substrate materials, precise element placement and effective shaping of the radiation patterns for beam steering. Moreover, combining the antennas with RF drivers boosts thermal conduction and reduces additional heating losses. This proves to be very important for managing the high power, high heat demands of sub-THz transmitters.

High Cost of Early-stage R&D and Prototyping

At extremely high frequencies beyond 100 GHz, AiP technology faces significant challenges stemming from material limitations, manufacturing precision, signal integrity and cost. The dielectric and conductor losses, surface roughness and other effects in the substrates, such as LTCC or glass, create issues related to cost, reliability and performance.

At mmWave and sub-THz ranges, very tight tolerances in antenna placement, substrate thickness, bonding and alignment are essential, as even slight variations can degrade beamforming, bandwidth and gain while lowering fabrication yields and driving up costs. Thermal issues further complicate integration, since densely packed modules must dissipate heat efficiently to prevent shifts in dielectric properties, thermal expansion and RF degradation.

Meanwhile, the proximity of active RF and digital electronics introduces challenges such as coupling, crosstalk, EMI/EMC concerns, spurious emissions and reflections, requiring robust shielding and grounding strategies. In addition to these technical hurdles, the high initial costs of AiP, driven by R&D, prototyping, specialized tools and low yields, make scaling difficult. Furthermore, greater integration and compaction also increase the cost and complexity of repair or rework. All of this must be addressed for widespread adoption to occur.

What's Next in AiP

It is not just about working an antenna on a chip and calling it a day—the real magic is in the details we barely see, such as the materials, design hacks and how it was built. Researchers are developing new dielectrics that barely lose signal and offer significant durability. We discuss glass, silicon, LTCC and sometimes organic materials, all mashed together. And for packaging, fan-out wafer-level, flip-chip basically, whatever keeps the electrical bugs out.

Mass production is another beast. Factories need to deal with tolerances, crank up yields and get everyone using the same shapes and test routines. Modeling and simulation tools are also becoming increasingly sophisticated, eliminating the need to physically build as many prototypes. Modular AiP arrays are also available, so we can easily add a few to enable modular scalability.

And then come the "do-it-all" modules. Multi-band, multi-function devices operating across sub-6 GHz, mmWave and sub-THz frequencies, all coexisting in one compact package. Some even incorporate radar, localization, or beamforming chips. Fewer parts, less cost, more features. But here is the kick: the more stuff you cram into a tiny box, the hotter it gets. Thermal management is more than a buzzword — it is a matter of survival in modern electronics. Engineers are turning to thermal vias, heat spreaders, strategic module layouts and even full-scale cooling systems to keep high-power base stations running efficiently.

Current Market Scenario and Trial Stage References

The AiP market is in the process of inflection from 5G commercialization to early 6G research and prototyping. It has been available in 5G smartphones and customer-premises equipment since early 2025 and is now widely deployed. This will form the basis for its future scaling. For 6G, the AiP is being tested in advanced labs for sub-THz and D-band frequency ranges, where initial applications have been noted in satellite communications, automotive radar and AR/VR headsets. Companies such as Qualcomm, ASE, Murata and Samsung are now working at scale on AiP modules using new materials and wafer-level packaging and applying co-design techniques to minimize losses and maximize yield.

The demand is majorly influenced by consumers who demand miniaturization and multi-band functions, along with low-cost integration, which is a key requirement for consumer devices. However, substrate losses, manufacturability precision and costs remain critical barriers. The 6G AiP market appears to be pre-commercial, with mass adoption anticipated after 2030, as announced by Qualcomm at its Snapdragon Summit 2025.

Shaping the 6G Era: What 6G AiP Might Look Like

The National Institute of Standards and Technology Communications Technology Laboratory (NIST CTL) is leading the way in 6G research, setting the stage for a future wireless world that is intelligent, robust and ubiquitous in its integration into daily life. As wireless communication transitions from 5G to 6G and beyond, NIST CTL strives to meet both the new technological challenges and the increasingly complex opportunities that arise from this transition.

The future of AiP technology points toward hybrid composite structures that integrate multiple functions such as communication, sensing and imaging within a single unit, enabling devices to handle both data transmission and environment awareness or localization. Sub-THz AiP modules are expected to mature rapidly, particularly for high-capacity or low-power network deployments, as well as backhaul and short-range, high-throughput applications such as indoor connectivity or AR/VR experiences.

Greater intelligence will also be embedded into AiP designs through adaptive beamforming and reconfigurable antennas, using tunable or switchable elements, or even advanced materials like meta-surfaces and smart surfaces with alterable electromagnetic properties. At extremely high frequencies, integration with optical and photonic components may become feasible, offering new opportunities for interconnection and device performance enhancements.

Furthermore, the growing diversity of applications, ranging from wearables, smart glasses and drones to vehicles, demands highly customized AI/ML (Artificial Intelligence/Machine Learning) solutions tailored to specific shapes, orientations and power or thermal constraints. With modularity and advanced design tools, these solutions enable rapid adaptation across form factors.

Looking for Consulting & Advisory Projects