Bio-Based Propylene Glycol: Driving Green Innovation and Low-Carbon Solutions

In-depth market intelligence to support growth and planning.

Evolution of Bio-Based Propylene Glycol

|

Year |

Key Milestone |

|

1997 |

Ø Some initial studies recognized

copper chromite catalysts as more effective for glycerol hydrogenolysis to

propylene glycol under moderate conditions. |

|

2007 |

Ø Comparative analysis of ruthenium

(Ru) and platinum (Pt) carbon-supported catalysts in aqueous glycerol

hydrogenolysis. Ø Exploration of how base additives impact

selectivity between propylene glycol and ethylene glycol. |

|

2011 |

Ø Archer Daniels Midland (ADM)

started its first commercial production of bio-based propylene glycol at its

Decatur, Illinois, U.S. plant. The facility began startup operations in late

March and started producing industrial-grade, biobased propylene glycol. |

|

2012 |

Ø Oleon has started a new

manufacturing plant to produce bio–based PG from glycerin in Ertvelde,

Belgium. This is the first plant to have glycerine to propylene glycol

via liquid-phase hydrogenolysis over a copper catalyst process. This process was

developed and licensed by BASF and jointly realized with Oleon. |

|

2015 |

Ø Research explored generating

hydrogen in situ, from aqueous phase reforming glycerol to feed

hydrogenolysis, decreasing external H₂ needs and simplifying plant utilities.

This line of work aimed to lower operating costs and H₂ risks. |

|

2021 |

Ø Research pushed Catalytic Transfer Hydrogenolysis

(CTH) and aqueous-phase reforming approaches (using glycerol as both H₂

source and substrate) to reduce external H₂ demand and energy intensity,

which is essential for plant economics and footprint. |

|

2022 |

Ø Various groups issued papers or

articles mentioning new Cu–Zn–Mg/La oxide supports, promoted metals and

bimetallic catalysts that achieved very high reported yields. Papers also

documented improved resistance to deactivation and leaching, a key factor in

longer commercial runs. |

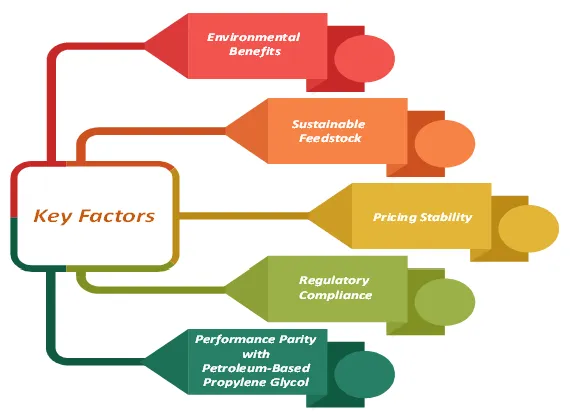

Key Factors that Accelerate the Adoption

of Bio-Based Propylene Glycol

- Environmental Benefits: The manufacturing process of bio-based propylene glycol emits nearly 60% fewer greenhouse gases than petroleum-based propylene glycol. This helps reduce industrial carbon emissions and supports global climate targets.

- Sustainable Feedstock: Bio-based propylene glycol is produced from renewable feedstock such as glycerin, glucose and sorbitol, decreasing reliance on fossil fuels and promoting a circular economy. The production of bio-based propylene glycol can valorize waste glycerol from biodiesel production, offering a sustainable chemical route and supporting the bioeconomy.

- Pricing Stability: Derivatives of crude oil can experience significant price fluctuations in the event of major global events. Prices for bio-based products tend to be more reliable.

- Regulatory Compliance: Government regulations supporting the bio-based economy have led to an increase in biodiesel production, resulting in an abundance of waste glycerol available as a low-cost feedstock for producing bio-based propylene glycol.

- Performance Parity with Petroleum-Based Propylene Glycol: Bio-based propylene glycol exhibits similar safety, stability and functional performance to its petroleum-derived counterpart, making it a suitable substitute across various end-use industries, including food, pharmaceutical and care, without compromising functionality.

Industry-Wise Applications of Bio-Based Propylene Glycol

|

Industry |

Application |

Benefits |

||

|

Pharmaceuticals |

Solvent, stabilizer and carrier in oral, topical and

injectable medications |

Enhances drug solubility and bioavailability, ensuring

consistent delivery of active ingredients. |

||

|

Cosmetics

and Personal Care |

|

|

||

|

Food

and Beverages |

|

|

||

|

Automotive

and Industrial Fluids |

|

|

||

|

Marine

and Transportation |

|

|

||

|

Construction

and Coatings |

Adhesives, sealants and coatings |

Enhances product performance while supporting

sustainability. |

||

|

Unsaturated

Polyester Resins (UPR) |

|

|

Technological Advances and Innovations in Bio-Based Propylene Glycol

- In 2024, researchers from Dalian University developed a cobalt-on-alumina catalyst promoted with silver (CoAg/Al₂O₃) that does not require prereduction treatment. Silver (Ag) promotes the in situ decrease of Cobalt (II,III) oxide (Co₃O₄) and generates oxygen vacancies, which facilitate hydrogenolysis under high glycerol concentrations. This simplifies catalyst preparation and maintenance.

- In 2024, a new method was developed using 12-crown-4 ether during impregnation to prepare copper on silicon dioxide (Cu/SiO₂). The catalyst yields more than 97% of propylene glycol with low carbon–carbon bond cleavage (C–C cleavage) side products in vapor-phase glycerol conversion under ambient hydrogen gas (H₂) flow. It maintains performance over ~98 hours of time-on-stream. Mega-high selectivity and stability are innovative, where stability refers to the catalyst’s ability to maintain its high activity and selectivity over long operational periods without degradation or loss of performance

Future Outlook

Strategic Takeaways for Industry Leaders

Looking for Consulting & Advisory Projects