Bio-solvents: Sustainable Alternatives Driving Green Chemistry and Industrial Innovation

In-depth market intelligence to support growth and planning.

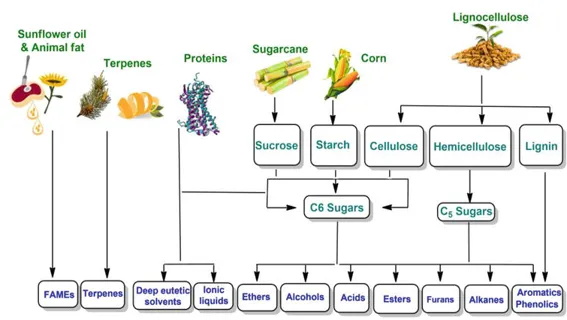

Source: The Various Sustainable Solvents Derived

from Biomass, IntechOpen, 2025

The primary processing methods include biochemical and thermochemical conversion. Using one or a combination of these processing techniques, several classes of bio-based solvents, including alcohols, esters, ethers, alkanes, aromatics and neoterics can be manufactured.

Examples of bio-solvents include d-Limonene, 2-methyl tetrahydrofuran (THF), dimethyl carbonate (DMC), ethanol, methyl soy and ethyl lactate. They are less toxic, and therefore, less odorous and harmful to the environment. The production of bio-solvents also reduces carbon dioxide and volatile organic compounds (VOCs) during the production process. This is crucial for companies seeking to comply with increasingly stringent environmental regulations. Additionally, natural solvents protect worker health and lower the risk of occupational illness.

Bio-solvents are easier to treat in exhaust streams and wastewater, resulting in lower operating costs. Products using certified green solvents often meet international standards, such as Green Label and Leadership in Energy and Environmental Design (LEED), which boosts corporate brand value and reputation. Advancements in biotechnology and the use of renewable raw materials are making bio-solvents more cost-effective. This lays the groundwork for gradually replacing petrochemical solvents and expanding into key industrial markets. Bio-solvents not only deliver economic value but also contribute to global sustainability goals. The trend toward green globalization and biodegradable solvents will be an essential driver of the circular economy in the near future.

Evolution of Bio-solvents

|

Period |

Description |

|

Pre–1990 |

The production of acetone, butanol and ethanol through fermentation

processes was the first instance of biomass- and fermentation-based solvent

processes. The use of inexpensive petroleum derivatives largely superseded

the use of this method. As a result, solvent production was confined to a

niche market. |

|

1990–2000 |

The increase in regulations concerning health and the environment,

more specifically the VOC and solvent emission regulations, fueled the desire

for greener alternatives. The concept of using biomass as a feedstock for the

production of chemicals and solvents began to gain traction, although limited

commercial applications were available. |

|

2000–2010 |

The number of funded research and pilot projects concerning bio-solvents

(alcohols, esters and ethers) began to increase. Academic discourse began to

classify and assess bio-based solvents, and the literature started to shift

beyond solely R&D towards the demonstration scale. |

|

2010–2020 |

This decade saw bio-solvents move from concept to the mainstream of

industrial demand. Stringent European VOC and Registration, Evaluation, Authorization

and Restriction of Chemicals (REACH) regulations compelled industries to

explore low-toxicity renewable alternatives. For the large-scale production

of essential solvents such as ethyl lactate, 2-MeTHF, and d-limonene using

biomass as a feedstock, advancements have been made in biorefinery and

catalytic processing. In coatings, cleaning agents and cosmetics, manufacturers have started

using bio-solvents, backed by life-cycle studies, which indicate lower

greenhouse gas emissions (GHG) and carbon footprints. Commercialization of

green solvents began during this period. |

|

2020–Present |

Bio-solvents are maturing, technologies are upscaling, feedstocks are

broadening (including waste biomass and nonfood biomass), and new solvent

systems, such as NADES and ionic liquids derived from within biomass, are

emerging. The industry is moving toward a circular economy and biosolvents are

emerging as mainstream alternatives. |

Industrial Applications of Bio-solvents

|

Industry |

Application |

|

Coating Industry |

Bio-solvents replace toluene and xylene in water-based paints,

polyurethane and epoxy systems. In addition to reducing VOC emissions, they

also enhance occupational safety, reduce unpleasant smells and decrease fire

risks. |

|

Industrial Cleaning |

These are used in cleaning electronic circuit boards, metals and

plastics. They are all-natural and biodegradable, with no toxic cleaning

residues. |

|

Printing Industry |

Water-based

inks are generally compatible with biodegradable solvents. Cleaning of

printing plates is facilitated and production efficiency is enhanced while

minimizing environmental pollution. |

|

Adhesives |

These are used as evaporation (EVA) solvents in polyurethane (PU) and acrylic

adhesives. Using an alternative to petrochemical solvents ensures that the

end product is safer for consumers and the environment. |

|

Bioplastics |

The bio-solvents find applications as reaction and diluent solvents in

biodegradable plastics like poly lactic acid (PLA) and polyhydroxyalkanoate

(PHA). |

|

Pharmaceutical and Cosmetics |

Bio-solvents are used for the extraction of flavoring and essential

oils. As a pharmaceutical excipient and as an excipient and carrier in

creams, lotions and other topical preparations, these bio-solvents ensure

safety and quality. |

Source: Company website, published articles and press

releases

Innovations and Technological Advances in Bio-solvents

- Natural Deep Eutectic Solvents (NADES): These are low-cost alternatives that are utilized in biodiesel manufacturing and upgrading biomass into valuable chemicals such as 5-hydroxymethylfurfural. Their adaptability and potential for recycling make NADES specifically attractive in terms of sustainable chemical practices. NADES are suitable for biomass conversion and metal recovery.

- Water as a Bio-Solvent: Water is used widely as a bio-solvent due to its harmless, abundant and multipurpose nature for reactions such as hydrolysis and extraction processes. Furthermore, its role as a solvent is unparalleled. Multiple substances dissolve in water, making it essential for countless chemical reactions. Water’s exclusive properties also permit it to facilitate temperature regulation in industrial processes, a crucial factor for maintaining optimal conditions.

- Nanotechnology Integration: Bio-solvents are utilized as media for nanoparticle synthesis, contributing to advancements in medicine, energy storage and electronics. As a sustainable alternative to conventional chemical reagents, bio-solvents have become a successful medium for the manufacture of nanoparticles.

Challenges of Using Bio-solvents:

- High Initial Cost: The production of bio-solvents, such as glycerol derivatives, lactate esters, or NADES, incurs a high initial cost, as the process often requires specialized equipment and techniques compared to traditional solvents.

- Scalability Issues: Several newly introduced bio-solvents encounter difficulties in scaling up their production for industrial use. Furthermore, large-scale production may present challenges to feedstock supply, and logistical and technical problems may hinder the faster adoption of the new solvents in the industry compared to conventional ones.

- Stability Concerns: Bio-solvents may change their properties or break down gradually, particularly at high temperatures or pressures, or even at very low temperatures.

- Cost Saving Strategies: Streamlining manufacturing methods, using abundant raw materials, and recycling solvents will be crucial to reducing the high initial costs of bio-solvents.

Future Outlook:

In the ongoing research, the primary focus is on developing bio-solvent sustainability, its applications in state-of-the-art technologies, and overcoming issues such as limited data for novel uses. These renewable substitutes are expected to contribute directly toward carbon neutrality and green chemistry by upgrading solvent systems. Future studies aim to further enhance bio-solvent performance by considering their utilization in new application areas and tailoring their features to meet the specific needs of different industries. Overcoming obstacles, including the scarcity of application-specific data, is crucial for broader adoption. Therefore, the inclusion of these bio-based solvents in various industrial processes can be a strategic force that helps guide the chemical industry toward a more environmentally friendly and sustainable direction.

Strategic Takeaways for Industry Leaders

Innovators utilize their expertise to transform the bio-solvents industry with the introduction of solvents such as glycerol derivatives, NADES and Cyrene. Their entry into the market is one factor that has become possible due to green chemistry regulations, corporate environmental, social and governance (ESG) initiatives, and sustainability efforts. There are strong prospects for securing supply contracts, validating production technologies and forming early partnerships, creating opportunities as large-scale production models continue to evolve. By helping companies demonstrate ESG leadership, an improved brand reputation and potential access to financing/investment may be derived from participation in initiatives focused on renewable chemical goods usage and sustainable program promotion.

For those manufacturing bio-solvents, major focus areas currently incorporate countries such as the U.S., Germany, the Netherlands, Japan, South Korea and India, as the combination of strong regulatory support and the presence of goals for industrial decarbonization is fostering early uptake of bio-solvents. New and emerging end-use applications include the formulation of pharmaceuticals, processing of biopolymers, battery recycling, formulation of agrochemicals, and the development of green coatings. Incentive structures for the integration of renewable chemicals in the EU Green Deal and the U.S. BioPreferred Program, for example, are also contributing to the emergence of Asia-Pacific production centers for bio-based products, particularly in India and China. For these bio-solvent manufacturers, the trends described above are likely to encourage the formalization of locally based production, research and development joint ventures, and sponsor- or customer-initiated agreements down the supply chain for sustainable solvents.

Looking for Consulting & Advisory Projects