Bioenergy with Carbon Capture Storage: Evolution, Projects and Path

Expert guidance to accelerate your market and strategy decisions.

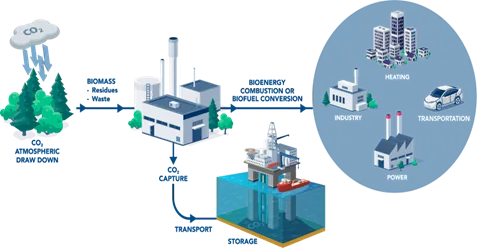

Bioenergy with carbon capture and storage (BECCS) involves capturing and permanently storing carbon dioxide from processes where biomass is converted into fuels or burned directly to generate energy. Plants absorb carbon dioxide as they grow, a process that helps remove carbon dioxide from the atmosphere. BECCS is a vital technology that reduces greenhouse gas emissions while generating energy. Its resourcefulness is demonstrated by the ability to utilize the full range of biomass feedstocks and multiple conversion pathways.

BECCS is a highly adaptable technology that can be applied to various end-use industries, including biofuel plants, waste-to-energy plants, power and heat plants, biogas plants and heavy industry. Carbon capture in BECCS typically occurs during biomass combustion, fermentation, or gasification processes, where carbon dioxide is separated from flue gases and either permanently stored underground or utilized in applications such as enhanced oil recovery, chemical synthesis and the production of building materials. After carbon dioxide is captured, it must be transported and stored and can even be reused.

Source: Babcock & Wilcox Enterprises Inc

Milestone in the Evolution of BECCS

- Previous 2000s Foundation: The Establishment of the Carbon Capture and Sequestration Technologies program at MIT in 1989 was a milestone in this sector. A natural extension of this technology was its application to reduce carbon dioxide emissions from biomass-fired power plants. Robert Williams of Princeton University hinted at BECCS in 1998 by stating the sequestration of captured carbon dioxide and the decarbonization of biomass fuels, but the focus of the report was on the manufacturing of hydrogen from biomass. In 2001, the carbon capture storage (CCS) for coal-fired power plants was already underway.

- Acknowledgement in Climate Policy Framework and Initial Project Pipeline (2000–2010): In 2005, the Intergovernmental Panel on Climate Change (IPCC) special report recognized biomass among carbon dioxide point sources suitable for storage and capture, formally embedding BECCS in policy discussions. In the mid-2000s, the integrated assessment model began to include BECCS, indicating its interest in achieving net-zero harmful emissions. By 2010, around 16 BECCS projects were identified at various stages, including planned, proposed, or research pilot. However, a large commercial project has not yet been deployed.

- World First Large-Scale Demonstration (2010–2015): Illinois Basin-Decatur Project injected around one million tons of carbon dioxide derived from biofuel manufacturing into a saline reservoir, the Mt. Simon Sandstone, in Decatur, Illinois. Operational injection started in 2011 and was completed in 2014.

- Research Facilities Started Demonstration and Policy Instruments were Introduced (2015–2020): The pilot and research facilities have initiated demonstrations in various regions. For instance, Stockholm Exergi, in Sweden, initiated a pilot facility in 2019, associated with the Värtan CHP plant, to test the BECCS technology. Governments of some countries, such as the Netherlands, changed their subsidiary framework to include emission reduction incentives and CCS.

- Large Scale Project Investment and Policy Pull (2020–Present): Emergence of policy tools, for instance, in 2022, the UK’s hydrogen innovation program was announced, which supports technologies that can create hydrogen from biogenic feedstocks and be combined with carbon capture. In 2025, Stockholm Exergi declared the world’s first large BECCS using Capsol’s carbon capture technology.

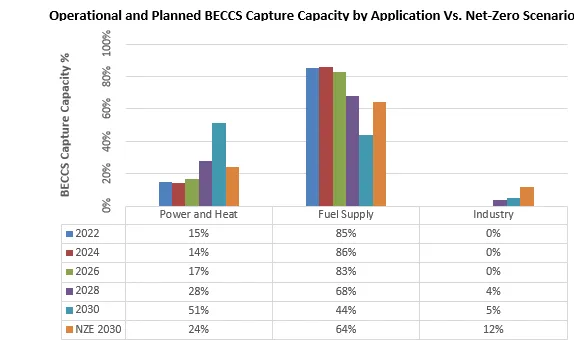

Bioethanol Dominates BECCS; Power and Industry are Emerging

- According to the International Energy Agency (IEA), around 70 additional bioethanol facilities are planned to start operation by 2030, totaling just 20 million tons of biogenic carbon dioxide capture capacity. Over the last three years, project announcements have suggested that the BECCS project pipeline is diversifying, with an increasing number of capture projects in the power, hydrogen, cement and heat sectors.

- Approximately 30 million tons of biogenic carbon dioxide are expected to be captured from heat and power plants by 2030. In Denmark, the two combined heat and power plants started construction in December 2023. They were awarded a contract by the Danish Energy Agency in 2023 as part of the Carbon Capture, Utilization, and Storage (CCUS) subsidy scheme, which provides financial incentives for CCS projects. The scheme helps minimize investment risks and encourages the early, large-scale deployment of BECCS technologies.

- Seven cement plants have announced plans to integrate biomass feedstock in the clinker production process and retrofit CCUS. These include the Brevik Norcem plant in Norway, currently under construction; the Edmonton cement plant in Canada; the GeZero carbon capture project in Germany; the “Go4ECOPlanet” project in Poland and others, all of which are at the advanced stage of development.

- Three projects also aim to CCUS retrofits at pulp and paper mills, including Hokuetsu pulp plant, as part of the East Niigata area CCS hub, which announced its feasibility in 2023.

- There are plans for five hydrogen facilities to run fully or partly on biomass with CCUS, with two additional facilities announced in 2023 in the U.S.

Operational and Planned BECCS Capture Capacity by Application Vs. Net-Zero Scenario 2022-2030

Source: IEA, 2024

Note: NZE: Net-Zero Emission

Innovation in Capture and Biomass Conversion Technologies

- Carbon dioxide capture from bioethanol production is the most mature BECCS route, with operations dating back to the late 2000s. Since 2020, carbon dioxide capture at biomass combustion plants has been at the commercial demonstration stage, with the commissioning of a capture unit at Mikawa Power Station, located in Japan. However, large-scale gasification of biomass for synthetic gas applications is still at the large prototype stage.

- In the industry, biomass co-firing is already commercial in cement plants, steel blast furnaces and pulp and paper mills. Carbon dioxide captured from kilns and blast furnace off-gas is still at the demonstration or prototype stage. The world’s first commercial carbon dioxide capture unit on a cement kiln is currently under construction, with commission scheduled for 2025.

- Chemical absorption is the established method used for capturing carbon dioxide in BECCS systems, but it requires high amounts of energy for solvent regeneration. To overcome this, new low-energy alternatives such as solid adsorption and membrane-based capture are being explored. For instance, since 2022, Drax, a power company in the U.K., has been piloting a solid-adsorption capture pilot using metal-organic frameworks at its North Yorkshire incubation hub.

- Work to demonstrate large-scale biomass gasification for synthesis gas applications is also underway, looking to decrease capital costs and raise feedstock flexibility. Projects include one on waste in the U.K. and one on woody biomass for biomethane production in Sweden.

Rising Funding in Bioenergy with CCS Projects Boosting Research and Development

Investment in BECCS projects is rising rapidly across all applications, including biofuel plants, waste-to-energy plants, power and heat plants, biogas plants and heavy industry. Funding is aimed at research and development activities of several BECCS applications, as well as specific commercial projects.

- In May 2023, Denmark awarded the first CCUS subsidy tender to a 0.4 million-ton-per-year BECCS project that is planning to capture carbon dioxide in 2025, with full operation expected by early 2026, at two biomass-fired power stations for dedicated storage.

- In February 2024, approximately $100 million was announced for carbon dioxide removal (CDR) pilot projects, including BECCS in the U.S.

Future Outlook

Bioenergy with carbon capture and storage is emerging as a crucial renewable technology that can produce energy while eliminating harmful emissions, thereby positioning it uniquely in the global transition to net-zero. Although some regions, including North America and Europe, are developing policies to incentivize the deployment of CCS technologies in bioenergy systems, the incentives need to be more attractive, long-term and more widespread to increase confidence among investors. With the right policy signals and supportive frameworks, BECCS has the chance to become a key tool in global efforts to decrease atmospheric carbon dioxide and achieve net-zero climate targets. End-use industries and companies are increasingly seeking sustainable solutions to meet Environmental, Social, and Governance (ESG) commitments and reduce carbon footprints, thereby creating demand for carbon removal technologies.

Strategic Takeaways for Industry Leaders

Bioenergy with carbon capture and storage is transitioning from pilot projects to early-stage development, led by pioneers such as Stockholm Exergi. The market remains policy-driven, with schemes such as Denmark's CCUS tender shaping deployment. Strategic opportunities lie in securing carbon removal contracts, validating technology and establishing early partnerships, as scalable models are still in development. Contribution to initiatives such as carbon removal contracts and sustainability programs enables companies to demonstrate ESG leadership, potentially enhancing their reputation and access to financing.

Looking for Consulting & Advisory Projects