Bioprinting for Kidney Disease

Tailored research built around your exact strategic priorities.

Renal Diseases Prevalence

The world faces an escalating crisis because kidney problems have become a major health crisis for numerous populations. Patient registries estimate that between 700 million and 850 million people suffer from kidney damage or complete kidney failure. The number of patients requiring kidney failure treatment increased from 5.3 million in 2023 to 10.5 million in 2024. The rising statistics indicate the seriousness of this issue, which demands innovative treatment solutions.

The current treatment options for patients consist of dialysis and kidney transplant procedures. The dialysis process drains patients of their energy, leaving them feeling extremely weak and drained. The number of available donor kidneys does not match the growing need for transplants at any given time. The number of patients on transplant waiting lists keeps increasing while transplant recipients experience additional health issues because their bodies reject the donated kidney. Scientists are currently investigating 3D bioprinting as a method to create artificial kidneys because of the ongoing challenges in treatment. The successful deployment of this technology would lead to easier medical procedures and save more lives, thereby reducing the expected shortage of available donor organ.

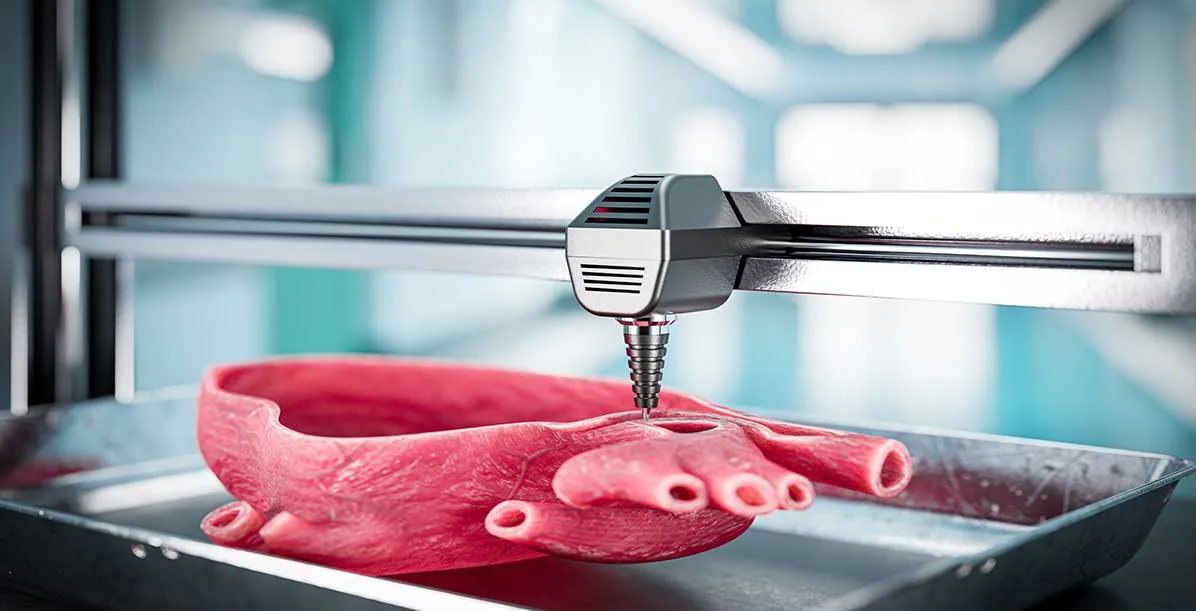

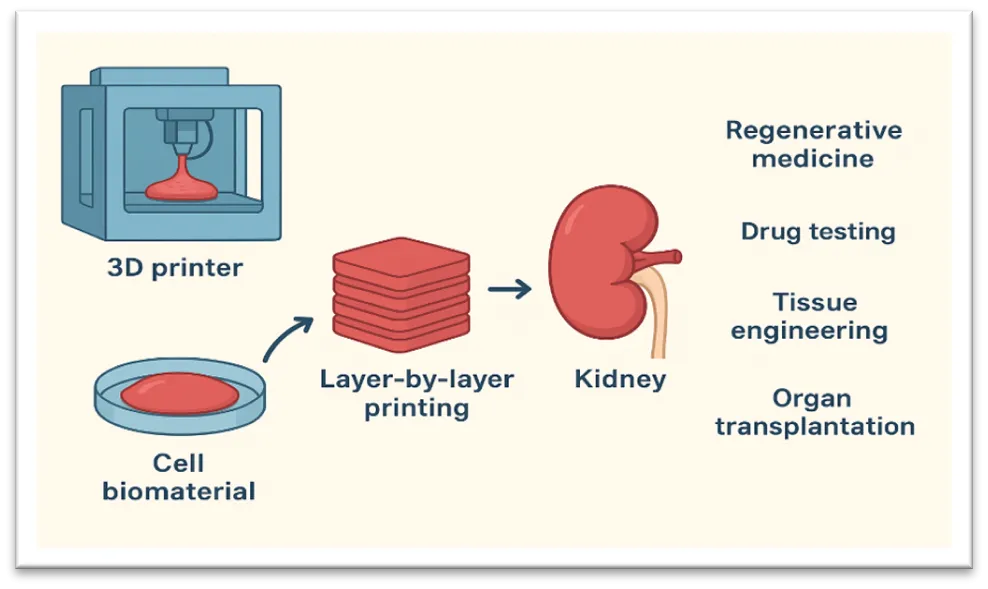

Basics of Bioprinting

3D bioprinting is an advanced method that constructs organ-mimicking tissues by depositing living cells, biological materials and active compounds layer by layer with meticulous accuracy. Employing customized “bioinks,” this approach replicates both the structure and functionality of real organs, presenting potential uses in regenerative therapies, tissue fabrication, pharmaceutical testing, and possibly, organ replacement.

Evolution of Bioprinting

A significant step toward the development of the first artificial organ produced in a lab was taken 25 years ago when Wake Forest University initially proposed the idea of a spatial scaffold. In 2003, Thomas Boland of the University of Texas at El Paso obtained a patent for a modified inkjet printer that he had created, which served as the basis for modern bioprinters. The invention enabled scientists to perform initial bioprinting research with biological substances. In 2010, Organovo introduced the NovoGen MMX bioprinter to the market, enabling scientists to create fundamental tissue and blood vessel structures without using cell scaffolds. The world has directed its research toward developing progressively sophisticated structures, which now include tiny kidney models, liver tissue constructs and heart tissue replicas.

Current Market Trend

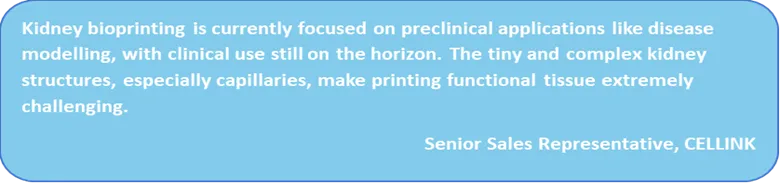

The current state of 3D bioprinting technology allows for rapid development, but it has not reached the stage of producing complete organs. The main uses of 3D bioprinting technology focus on tissue regeneration, organoid creation and drug testing applications. The technology drives market expansion through its extensive use in regenerative medicine, personalized therapies, drug discovery and research applications. The current timeframes do not support the production of complete organs through 3D bioprinting technology despite its rapid development. The main applications of 3D bioprinting technology include tissue regeneration, organoid development and drug testing. Nonetheless, the technology's wide spectrum of uses in regenerative medicine, customized therapies, medication discovery and research drives its market growth. Various institutions, labs and businesses are currently working to generate complicated kidney tissues.

In March 2025, Humacyte, a commercial-stage biotech company specializing in implanted human tissue technologies, and Trestle Biotherapeutics, a preclinical company focused on developing successful bioengineered solutions for end-stage renal disease (ESRD), merged.

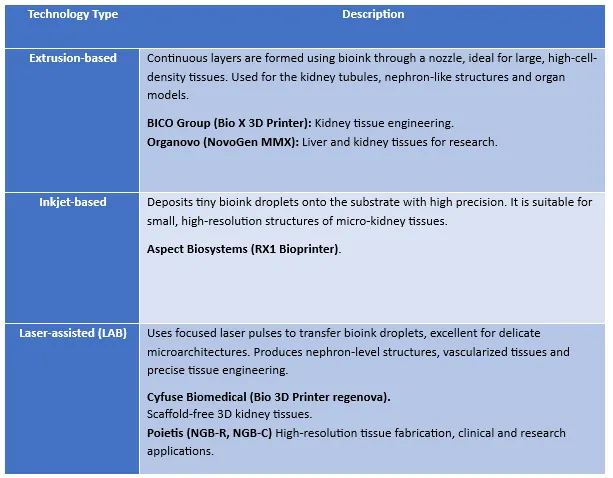

Bioprinting Platforms

Current Breakthroughs That Will Shape the Future of Kidney Bioprinting

- To provide individualized treatment, researchers created an automated 3D bioprinting system that creates kidney tumor organoids from patient-specific cells. By acting as tailored drug testing platforms, these bioprinted tumor models enable patient-specific therapy evaluation and aid in optimizing treatment plans for maximum efficacy.

- The University of Southern California (USC) researchers created lab-grown kidney constructs called 'assembloids' that function similarly to human kidneys. The assembloids demonstrate complete kidney functionality through their ability to filter blood, absorb proteins like albumin and produce hormones and urine. The research breakthrough enables scientists to create precise models of complex kidney diseases while developing new regenerative medical treatments.

- The longest-surviving human kidney organoid was produced by researchers from Tel Aviv University and Sheba Medical Centre, utilizing stem cell tissue engineering to mimic fetal kidney development patterns. It will be an essential tool for studying kidney disorders and associated therapies, as well as fetal kidney development.

- Early-stage research on miniature kidney structures: Maastricht University's study focuses on initiatives to bioprint tubular structures and tiny patches of kidney tissue for laboratory testing and early preclinical application. Although research on vascularization is still in progress, these constructs are not yet complete organs.

Market Players

Organovo: The company produces induced pluripotent stem cell-derived kidney organoids through its NovoGen MMX system, which operates through extrusion. The small tissue structures are used for drug testing and toxicity assessments in research environments, but they do not support complete organ transplantation. According to an economic study, the Novo Gen MMX bioprinter costs approximately $200,000 per unit.

BICO/Cellink: BICO’s BIO X series bioprinters and specialized bioinks are widely adopted in labs to create kidney tubules and organoids. Their adaptable platforms are standard in both academic and industrial settings for research and pharmaceutical testing. The cost for the Bio X series bioprinter is around $39,000.

Poietis: The company provides the NGB line, which uses laser-assisted and multimodal printing methods to create detailed tissue engineering products. While primarily applied to skin and cartilage, this technology is adaptable to micro-kidney constructs and organ-on-chip studies.

Cyfuse Biomedical: Cyfuse’s Bio 3D (Regenova) system organizes cell spheroids into three-dimensional structures. This scaffold-free approach supports vascularized tissue research and regenerative trials, although it does not yet enable the fabrication of complete kidneys.

Aspect Biosystems: Aspect’s RX1 platform leverages microvalve printing to develop kidney tissue models in academic collaborations. The company’s long-term focus is on advancing implantable therapeutic tissues.

Future Trend

The development of clinical prototypes is expected to transition from laboratory settings to initial human testing over the next decade.

- The achievement of this goal needs the following:

- Organ engineering platforms to integrate robust vascularization methods for successful development.

- The development of scalable manufacturing systems and regulatory systems to occur simultaneously.

The deployment of AI robotics and nanotechnology must align with the current state of technological development. The solution to these challenges will result in fully functional bioprinted kidneys that can serve as complete organs for transplantation, thereby transforming kidney disease treatment.

Conclusion

The current need for new treatment solutions arises from the worldwide prevalence of kidney disease and the limited access to dialysis and transplantation solutions. This is addressed through the production of kidney organoids, tissue models, and disease simulation systems, which support scientific research and services, as well as alleviate organ shortages and complications related to graft rejection. The 3D bioprinting technology offers promising applications in drug testing and personalized medical interventions. The development of implantable kidney constructs continues to advance due to advancements in bioprinting technology and increasing partnerships between biotech companies. The integration of bioprinting with AI robotics and nanotechnology demonstrates potential to build functional artificial kidneys, although scalability issues, vascularization problems and regulatory hurdles remain. The successful deployment of this innovation would transform kidney disease treatment while reducing global depende

Looking for Consulting & Advisory Projects