Building Scalable and Sustainable Strategies in Carbon-based Nanomaterials

Tailored research built around your exact strategic priorities.

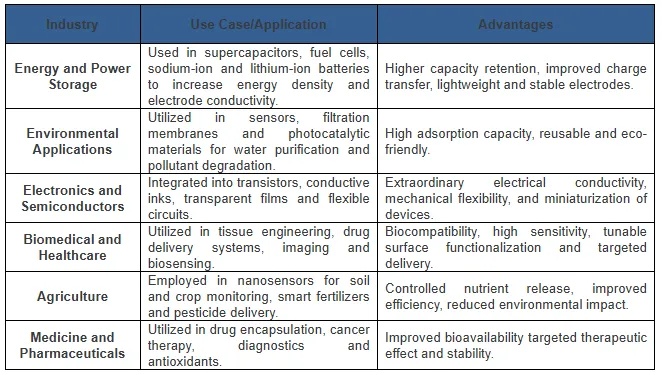

A family of carbon-based nanomaterials is mainly made of carbon with nanoscale structures. The scientific world is paying attention to carbon-based nanomaterials due to their high surface areas and their extraordinary electrical, magnetic, optical, catalytic and mechanical properties, which can be tuned by controlling factors, such as shape, size, functionalization and synthesis conditions. Owing to the wide variety of properties, carbon-based nanomaterials are utilized in several end-use industries: healthcare and pharmaceuticals, electronics and semiconductor manufacturing, energy and power storage, and environmental and chemical industries.

Source: Carbon

Nanomaterials, Springer Open, 2025

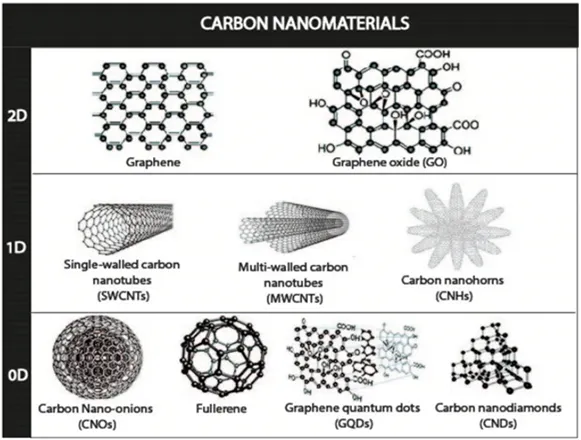

The major carbon-based nanomaterials include carbon nanotubes, fullerenes, carbon quantum dots, graphene and its derivatives, nanodiamonds, nanocones, and nanofibers. Carbon nanotubes are cylindrical graphene sheets that have outstanding conductivity and strength. Fullerenes are spherical carbon edges, such as C60, which are known for their electron affinity. Carbon quantum dots are nanoscale fluorescent particles utilized in sensing and bioimaging. Graphene is a single atomic layer of carbon atoms that has exceptional thermal and electrical performance. Nanodiamonds consist of sp3-carbon-bonded atoms with high chemical stability and hardness. Carbon nanofibers are elongated, filament-like structures known for their excellent mechanical strength and thermal conductivity, making them ideal for use in composites and energy storage applications. Carbon nanocones feature conical geometries that offer unique electron emission and field enhancement properties useful in sensors and emitters.

Various synthesis techniques are utilized to produce carbon-based nanomaterials. Standard methods include laser ablation, chemical vapor deposition, and arc discharge, which are extensively used to produce fullerenes and carbon nanotubes by vaporizing graphite at high temperatures. Chemical and mechanical exfoliation methods, such as Hummers method, are used to produce graphene and its derivatives from graphite. Catalytic growth and electrospinning are used for carbon nanofibers, while detonation, high-pressure, and high-temperature methods are applied for nanodiamonds. Solvothermal, hydrothermal and microwave-assisted methods are used to produce quantum dots.

Evolution of Carbon-based Nanomaterials

- Discovery of Nanodiamond Synthesis (1960–1970): In 1963, nanodiamond synthesis was discovered by K.V. Volkov, V.V. Danilenko, and V.I. Elin at the VNIITF in the Soviet Union. Each of these researchers accidentally discovered nanodiamond synthesis while learning about diamond synthesis through the shock compression of nondiamond carbon structures in blast chambers.

- Discovery of Fullerenes (1970–1980): Robert F. Curl, Richard E. Smalley, and Harold W. Kroto witnessed the mass spectra signals corresponding to C60 in a carbon vaporization experiment and found the spherical cage structure.

- Bulk Synthesis of Fullerenes (1980–1990): Wolfgang Krätschmer, Donald Huffman, et al created a method to manufacture gram-scale fullerene (C60) quantities, enabling broader experimentation.

- Identification Carbon Nanotube (1990–2000): In 1991, a new form of carbon, the carbon nanotube (CNT), was discovered by Sumio Iijima and his research team. This discovery marked a major breakthrough in nanoscience, as CNTs exhibited an exceptional length-to-diameter ratio and exceptional mechanical, electrical, and thermal properties, making them extremely influential in both fundamental research and practical applications.

- Isolation of Graphene (2000–2010): In 2004, Kostya Novoselov and Andre Geim utilized mechanical exfoliation to isolate monolayer graphene flakes from graphite. This occasion catalysed the 2D materials era and generated massive growth in graphene research.

- Commercial Production of Graphene (2010–2020): Samsung's research unit produced a novel synthesis method for single-crystal, large-area, and wafer-scale graphene. This was a step toward moving graphene from labs to commercial production, especially for the electronics industry.

- Composite Carbon-based Nanomaterials with Enhanced Functionality (2020–2024): Recent studies have demonstrated that combining carbon quantum dots with zinc oxide produces hybrid nanostructures exhibiting superior photocatalytic, energy storage and energy conversion performance. This development highlights the growing trend of composite carbon-based nanomaterials designed to integrate multiple functionalities for improved efficiency and stability.

Key Factors Accelerating the Adoption of Carbon-based Nanomaterials

Material Characteristics: Carbon-based nanomaterials such as carbon nanotubes, nanodiamonds and graphene have extraordinary mechanical strength, chemical resistance and electrical conductivity, making them suitable for aerospace, electronics and automotive applications.

Collaboration and Partnerships Boosting Commercial Adoption: Collaborations and partnerships between research institutes, government and end-use industries are enhancing the commercial adoption of carbon-based nanomaterials by funding pilot-scale production, R&D, and safe commercialization. For instance, the EU Graphene Flagship Project and the U.S. National Nanotechnology Initiative (NNI) endorse collaboration between academic institutes and companies.

Technological Developments

- Transforming Carbon-based Nanomaterials with Automation and Machine Learning Models: The incorporation of artificial intelligence (AI) with automated synthesis platforms has transformed the production of carbon-based nanomaterials. For instance, the introduction of Carbon Copilot (CARCO), an AI-driven platform that incorporates transformer-based language models tailored to carbon-based nanomaterials, data-driven machine learning models and robotic chemical vapor deposition, expedites the research of carbon-based nanomaterials synthesis.

- Sustainable and Green Production Methods: Advances in sustainable synthesis techniques, such as microwave-assisted synthesis, have enabled the production of carbon-based nanomaterials using bio-based materials, residues or wastes, thereby reinforcing the concept of green and sustainable production methods.

- Use of Quantum Engineering for Nanoelectronics: Research demonstrated quantum interference survives at room temperature; therefore, it paves the way toward the future realization of quantum interference-engineered carbon nanocircuitry operating at room temperature, which is an important step toward carbon-based nanoelectronics and quantum technologies.

- Carbon-based Nanomaterials in Environmental Remediation: Carbon-based nanomaterials are emerging as solutions for environmental applications such as wastewater treatment. Functionalized carbon-based nanomaterials, in combination with bacteria, have shown promise in offering a sustainable solution for water purification and pollutant degradation.

- Unique Hydrogen Evolution with Low Carbon-based Nanomaterials: The research demonstrated the strategic partial hydrogenation of carbon-based nanomaterials that could improve their electronic conductivity and serve as an effective approach to design catalysts for sustainable hydrogen production. This innovation offers a cost-effective and efficient catalyst, offering the broader adoption of greener energy technologies.

Source: BCC Research

Future Outlook

The potential of

carbon-based nanomaterials for a greener tomorrow is obvious through their

application in electronic devices and renewable energy. The commercial adoption

is boosting due to partnerships, collaborations, funding and R&D

activities. Moreover, commercial efforts, demonstrated by manufacturers such as

Samsung and Nanocyl, underscore the rising recognition of the significance of carbon-based

nanomaterials.

In Europe, strong sustainability

policies under the EU Green Deal

and Horizon Europe are accelerating

their adoption, especially in energy storage, lightweight

composites and environmental applications,

making the region a frontrunner in green material innovation. Globally, regions

such as the Asia-Pacific and North America are also

expanding research and industrial-scale production through collaboration

between the government and private sectors.

Recent research

demonstrates their role in innovative configurations, including catalysts for

hydrogen evolution and flexible sensors. But challenges such as environmental

impact and cost-effectiveness need to be addressed for widespread adoption.

With ongoing research, it is expected that carbon-based nanomaterials will

emerge, paving the way for a sustainable and eco-friendly energy future.

Strategic Takeaways for Industry Leaders

Carbon-based

nanomaterials are changing from laboratory innovation to industrial-grade

integration among various industries, such as electronics, biomedical and energy.

Leaders should prioritize application-driven R&D, scalable synthesis

methods and sustainable production pathways that help to stay ahead in the

competition. Strategic collaborations and partnerships between carbon-based

nanomaterials manufacturers, governments and end-user companies will be instrumental

in accelerating commercialization. The leaders who are adopting technology,

sustainability and partnership strategies will outline the next wave of

carbon-based, nanomaterial-enabled solutions across various end-use industries.

In addition,

integrating circular economy principles such as recycling carbon-based

nanomaterials from end-of-life products, optimizing material recovery and

minimizing waste during synthesis are going to be essential. This approach not

only enhances sustainability but also supports long-term value creation and

compliance with emerging global environmental standards.

Looking for Consulting & Advisory Projects