Elastocaloric Materials Market

Clear insight into competitor positioning and market share.

Figure 1. Illustration of reduced dimensions of

elastocaloric materials

Elastocaloric materials have applications in various industries, such as medical, industrial, residential, electronics, automotive and commercial. These materials are extensively used in the medical industry due to their biocompatibility. In the electronics sector, elastocaloric materials aid in cooling electronics by altering their temperature when subjected to pressure or strain. These materials enhance cooling performance and make electronic devices more eco-friendly. With the use of elastocaloric materials, electronic devices can be made smaller and quieter.

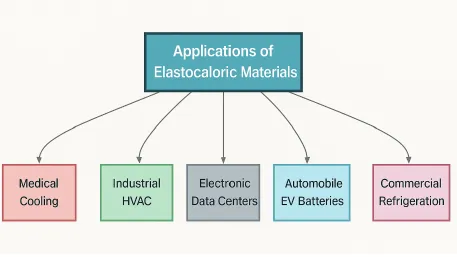

Applications:

Figure 2. Representation of various

applications of elastocaloric materials

Drivers and Challenges:

The surge in development of regulations aimed at reducing global warming is fostering the growth of the elastocaloric materials market. For example, the Kigali Amendment is an agreement under the Montreal Protocol aimed at reducing the use of substances that deplete the ozone layer. According to this regulation, by 2047, countries worldwide are required to reduce the supply and demand of hydrochlorofluorocarbons by approximately 80% to mitigate global warming. These stringent regulations are expected to foster the adoption of energy-efficient and environmentally friendly cooling technologies. Consequently, elastocaloric materials are expected to gain recognition as an effective alternative to conventional refrigerants, driving market growth.

According to the International Energy Agency, in 2024, around two billion air conditioners were in use globally, and the demand is expected to reach 5.6 billion by 2050. These air conditioners, primarily based on vapor-compression technology, account for approximately 15% of the overall electricity demand. This signifies that ACs consume a large amount of electricity and use refrigerant fluids, such as hydrochlorofluorocarbons. Elastocaloric solid-state cooling systems are efficient for minimizing the release of harmful liquid refrigerants, which contribute to global warming. They also have the capability of limiting the overall energy consumption of cooling systems. For instance, in March 2025, the Department of Energy predicted that elastocaloric solid-state cooling systems are likely to save more than 2% of the total U.S. annual energy use.

Elastocaloric solid-state cooling enables precise temperature regulation, enhancing thermal comfort in the home and office. However, elastocaloric materials are non-durable, which is a key challenge for the elastocaloric materials market. This restraint is likely to hinder the commercialization of elastocaloric cooling devices. Nevertheless, with the development of new devices that operate under compressive loading, the production of new material systems, and the use of innovative production methods, the issue can be tackled.

Key Research and Strategic Developments:

- In recent years, researchers have been employing advanced computer modelling and additive manufacturing, primarily 3D printing, to design new types of shape memory alloys with properties such as flexibility, strength, or operating temperature. This enables researchers to design miniature cooling devices. These next-generation shape memory alloys will be utilized for a wide range of applications, including personal electronics and energy-efficient buildings. Hence, this development of miniature cooling devices is expected to foster the growth of the elastocaloric materials market.

- In March 2025, researchers at the Hong Kong University of Science and Technology introduced the first kilowatt-scale elastocaloric cooling device. Unlike conventional vapor-compression technologies, the kilowatt-scale elastocaloric cooling device utilizes the elastocaloric effect for delivering efficient and environmentally friendly cooling. When outdoor temperatures range between 30°C and 31°C, the device can monitor indoor temperatures between 21°C and 22°C within 15 minutes. This development will represent a significant achievement in propelling the transition to high-efficiency cooling solutions in commercial environments.

- Key venture capital and growth investment groups operating globally offered venture capital investment to manufacturers of elastocaloric solid-state cooling technology in March 2025. These groups include Khosla Ventures, Extantia Capital, Kiko Ventures, Carrier Ventures, Goldman Sachs and Breakthrough Energy Ventures. This venture capital funding will enable the commercialization, scaling and broader adoption of elastocaloric materials across various cooling applications by driving research into elastocaloric materials.

Conclusion:

Currently,

industries are consistently looking for energy efficiency along with

eco-friendly cooling solutions. Factors such as a rise in environmental

concerns and stringent regulations imposed by the government on traditional

refrigerants are encouraging both end-users and manufacturers to adopt and

produce alternatives that help reduce greenhouse gas emissions. Elastocaloric

materials utilize temperature changes induced by mechanical stress to provide an

efficient and sustainable cooling mechanism. This property of shape-memory

alloys makes them a potential alternative to conventional vapor-compression

systems.

Elastocaloric

materials are gaining traction across numerous sectors, including commercial,

residential, automotive and electronics. This is attributed to the ability of

elastocaloric materials to offer enhanced performance with lower energy

consumption. Technological advancements, ongoing research, and increased

investments by key market players are driving market growth. Therefore, with a

surge in awareness of eco-friendly cooling solutions coupled with rising

government support, the elastocaloric materials market is expected to grow in

the near future.

Looking for Consulting & Advisory Projects