The Role of Low-Emissivity Glass in Shaping Sustainable and Smart Buildings

Clear insight into competitor positioning and market share.

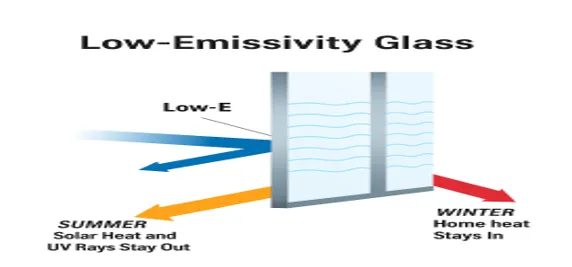

Low-emissivity glass, also known as Low-E glass, is a type of energy-efficient glass that helps reduce energy bills and consumption. Low-emissivity glass features a superior microscopic coating that reduces thermal transfer and retains heat in the room. In the summer, it helps keep the heat away, whereas in the winter, it retains warmth in the room. There are two types of low-emissivity glass coatings: passive coatings (hard coat) and solar control coatings (soft coat). According to Vitro Glass Education Center, various essential factors are used to measure the effectiveness of glass with low-emissivity coatings, which are as follows:

- Solar Heat Gain Coefficient (SHGC): This is the fraction of incident solar radiation that is admitted through the window. SHGC can be either radiated inward or directly absorbed and transmitted.

- Thermal Transmittance (U-Value): This is the rating that is given to a window based on how much heat loss it permits.

- Visible Light Transmittance (VLT): The amount of visible light that passes through the glass is measured by VLT.

- Light to Solar Gain: The ratio between the solar gain coefficient rating and the window’s visible light transmittance.

Source: Stanek Windows

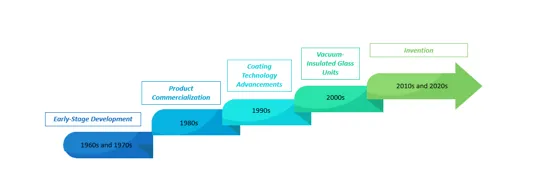

Evolution of Low-Emissivity Glass

Early-Stage Development (1960s–1970s): Efforts to produce low-emissivity glass began in the 1960s, but actual production did not commence until the 1970s.

Product Commercialization (1980s): By the late 1980s, the commercial use of low-emissivity glass had begun. The glass contained a metal oxide layer that allowed visible light to pass through and also inhibited heat from seeping outward. This glass was produced with various thin layers of gold that created a green tinge.

Coating Technology Advancements (1990s): In the early 1990s, glass producers revolutionized the fabrication of low-emissivity glass with the introduction of the first double-silver-coated glasses. These glasses featured two layers of multiple micro-thin layers of active/proactive performance materials, as well as silver. Double silver coatings allowed this generation of low-emissivity glasses to maintain the same levels of visible light transmittance as single silver low-emissivity coatings while raising their ability to block solar heat gain by more than 30%.

Integration with Vacuum-Insulated Glass Units (2000s): In 2000, Vitro launched the world’s first Solarban 60 glass, which has double-silver vacuum-tunable low-emissivity glass that permitted post-production fabrication.

Invention (2010s–2020s): Silver was utilized at the nanometer scale in low-emissivity coated glass, which was layered with other materials to give the glass anti-reflective properties. Thus, selectivity is achieved in the electromagnetic spectrum, allowing daylight to enter the interior of the building. Low-emissivity-coated glasses on this nanometric scale have characteristics that guard the interior from the harmful effects of sunlight due to their infrared and ultraviolet reflective properties.

Key Factors that Accelerate the Adoption of Low-Emissivity Glass

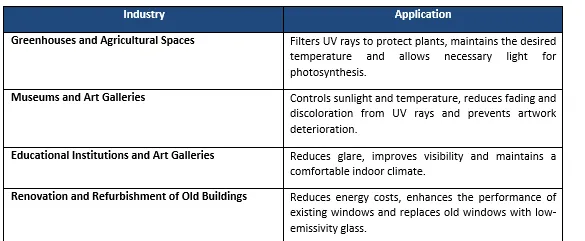

Ultraviolet Protection: Low-emissivity glass protects from ultraviolet rays. This helps inhibit the fading and deterioration of flooring, interior furnishings and artwork, while reducing health risks such as skin damage from prolonged exposure to ultraviolet rays. This UV-resistant glass is advantageous for homes with large windows and doors, retail stores, skylights, museums and sunrooms, where natural light is essential but UV damage is a concern.

Comfort: Low-emissivity glass helps maintain a constant indoor temperature, preventing frozen spots near windows in winter and excessive heat in summer. Enhanced thermal performance helps provide more comfort in both commercial and residential spaces.

Energy Savings: In the summer, a low-emissivity coating reflects the sun’s heat away, keeping interiors cooler and reducing the reliance on air conditioning. The low-emissivity coating reflects interior heat into the room during winter, reducing the need for additional heating. By increasing the insulation properties of windows, low-emissivity glass leads to substantial savings on heating and cooling costs.

Visual Appeal: Low-emissivity glass provides visual advantages without compromising its functions. It maintains high levels of visible light transmission, ensuring welcoming and bright interiors. It is available in several coatings and tints to match different architectural preferences and styles.

Examples of Buildings that Stand as Structural Proof of Low-Emissivity Glass Invention’s Aesthetic and Functional Appeal

Bank of America Tower in New York City, U.S, has achieved the first LEED Platinum certified commercial skyscraper due to its heat-reflecting low-emissivity glass curtain windows and walls.

The Crystal, based in London, U.K., is one of the world's most sustainable buildings, which uses low-emissivity glass to improve energy performance and reduce environmental impact.

Pearl River Tower in Guangzhou, China, is famous for its unique green design and incorporates low-emissivity-coated glass to reduce solar heat gain. According to the US Green Building Council, Pearl River Tower has achieved LEED Platinum certification.

Pixel Building in Melbourne, Australia, is a sustainable structure that features low-emissivity glass windows as part of its energy-efficient design strategy. The building also produces its own electricity and water, scoring a perfect 6-Star Green Star rating.

Recent Innovative Advancements

evelopment of Solar Low-Emissivity Glass: The introduction of solar low-emissivity glass has enabled the simultaneous control of both heat and solar radiation through a single coating. This development offers enhanced insulation compared to conventional double glazing, making it ideal for reducing heating and cooling loads in buildings. For instance, Saint-Gobain launched the ORAÉ solution in 2022, the world's first low-carbon glass, which provides a carbon footprint lower than the average European value of Saint-Gobain glass products. This innovation combines low-emissivity coatings with high-performance glazing to enhance energy efficiency and sustainability in building designs.

Triple-Glazed Low-Emissivity Units: Triple-glazed low-emissivity units consist of three layers of glass with low-emissivity coatings and inert gas fills, such as argon or krypton, between the panes. This design significantly enhances thermal insulation and daylight control compared to double-glazed systems, making them suitable for energy-efficient buildings. For instance, in 2025, Guardian Glass launched the SunGuard SNX 60+ glass in North America. This new triple silver low-emissivity coated glass offers improved energy efficiency and is ideal for a range of architectural applications.

Future Outlook

Advancements in energy efficiency and sustainability formed the future of low-emissivity glass. Innovations such as triple-glazed units, solar-control coatings and integration with vacuum-insulated glass are improving acoustic insulation and thermal performance.

Moreover, the development of smart low-emissivity glass and the adoption of sustainable production practices are expected to further propel market expansion soon. The construction industry is placing a high value on energy efficiency, which will play a crucial role in shaping the future of building performance.

Strategic Takeaways for Industry Leaders

Low-emissivity glass is not just a value-added option but a fundamental element of sustainable building design. With stringent energy codes, increasing demand for green construction and rising emphasis on occupant comfort, industry leaders are focusing on investing in advanced coating technologies, building partnerships with builders and architects and highlighting large public projects or iconic buildings that showcase their performance. Early movers will play a crucial role in establishing performance standards and defining benchmarks for next-generation, energy-efficient architecture

Looking for Consulting & Advisory Projects