Mesoporous Material Market:

Clear insight into competitor positioning and market share.

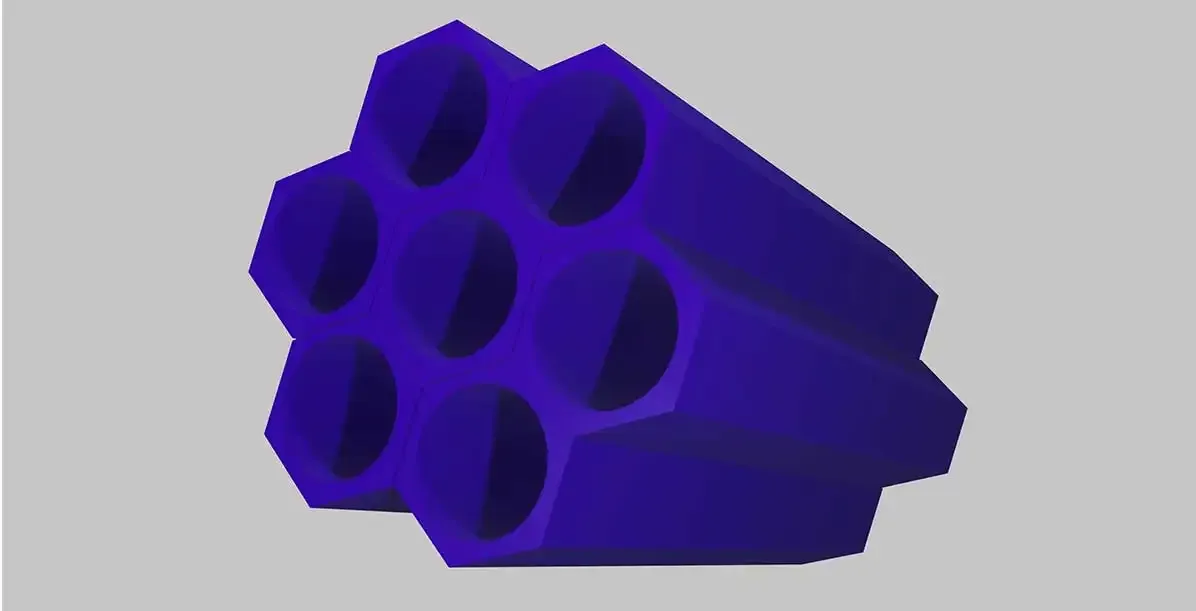

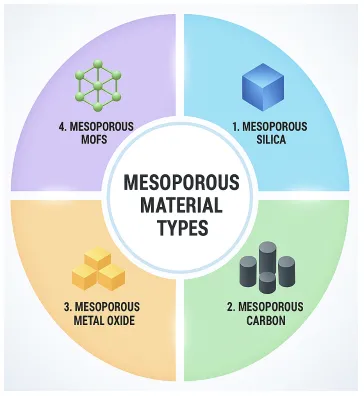

Mesoporous materials are substances that contain pores with diameters ranging from 2–50 nanometers. Since mesoporous materials have a large surface area and tunable pore size, they are utilized as superior adsorbents to eliminate pollutants. They find applications in separation, catalysis, drug delivery and electrodes in technologies such as fuel cells and supercapacitors. Recent methods used to synthesize mesoporous materials include hydrothermal synthesis, microwave synthesis and the sol-gel method. They are also extensively utilized in sensors, where the high surface reactivity and stability of mesoporous materials help enhance the sensitivity and detection accuracy of the sensors. Mesoporous carbon, mesoporous metal oxide, mesoporous silica and mesoporous metal-organic frameworks (MOFs) are some of the major types of mesoporous materials.

Fig 1: Types of mesoporous material

Drivers and Restraints:

Mesoporous materials such as alumina, carbon, mesoporous silica, titania and metal-organic frameworks can be produced from various inorganic and organic precursors and are extensively utilized in drug delivery vehicles. They have a large surface area and variable pore sizes, which makes them highly efficient at absorbing pollutants, heavy metals and organic contaminants from water. These materials are highly effective in removing microorganisms, including bacteria, viruses and fungi, thereby helping to mitigate indoor air pollution. It helps mitigate water scarcity and address pollution concerns worldwide. They can remove various pollutants, contributing to the eco-friendly management of the environment. As a result, the adaptability of these materials in environmental applications, combined with continuous breakthroughs in material science, is propelling the growth of the mesoporous materials market.

Mesoporous silica nanoparticles are gaining popularity in biotechnology due to their tunable pore size (2–50 nanometers), biocompatibility, high surface area and ease of surface functionalization. Mesoporous materials provide excellent support for enzymes, which are essential for a wide range of biotechnological applications. These unique properties make mesoporous silica materials efficient for use in biosensing, targeted drug delivery and imaging. Mesoporous materials are widely used to enhance enzyme stability and reusability, which consequently facilitates their broader acceptance in biomedical research. According to the U.S. Biotechnology Industry Report 2024, the U.S. led the global R&D efforts, accounting for 51.1% of all pharmaceuticals in development as of 2023. Besides, China ranked second with 23.6%. Several European countries, such as Germany (11%), France (10.1%), and Spain (9.5%), are also among the top ten in terms of a strong R&D pipeline. Thus, the growing R&D in the biotechnology industry, coupled with the wide-ranging applications of mesoporous materials in the sector, will drive demand for m

However, the high production costs associated with the complex synthesis methods of mesoporous materials are one of the key restraints to market growth. This often requires expensive precursors and advanced equipment, leading to higher production costs and making mesoporous materials less accessible for cost-sensitive applications.

Fig 2: Synthesis and applications

of mesoporous materials

Key Manufacturers and Strategic Developments:

Some of the key manufacturers operating in the mesoporous materials market include W.R. Grace & Co., Sasol Limited, BASF SE, Minerva Carbon, Taiyo, ACS Material LLC, Nippon Sanso Holdings Corporation, Mitsui & Co., Albemarle Corporation, Clariant AG and ExxonMobil Corporation. In August 2025, Minerva Carbon, based in Mülheim, received approximately $2 million in funding under the EXIST program, a German government initiative aimed at supporting innovative startups. This fund was provided by the German Federal Ministry for Economic Affairs and Energy. The company is committed to commercializing mesoporous high-performance carbon materials to enhance the durability, efficiency, and performance of batteries and fuel cells. Minerva Carbon aims to integrate advanced research for the development of optimized carbon materials in an efficient and sustainable manner. This strategy is expected to propel the adoption of mesoporous materials and drive market growth.

Future Outlook:

Combining mesoporous materials with other functional nanomaterials, such as nanowires, nanoparticles, and graphene, could lead to applications in optoelectronics and biomedicine. Mesoporous materials can be utilized to enhance drug loading and demonstrate notable potential in various biomedical applications, including drug delivery, photothermal therapy, photodynamic therapy and biosensor development. Due to their distinct structural properties and surface functionalization capacity, these materials can adsorb a greater quantity of compounds and protect them from environmental degradation.

Mesoporous siliceous materials, synthesized from renewable precursors using environmentally friendly sol-gel and hydrothermal methods, are gaining high popularity. Glyceryl monostearate serves as an economical, commercially available porogen, while silica is sourced from rice husk, an underutilized agricultural byproduct. Thus, production of mesoporous materials from renewable sources is expected to offer ample growth opportunities. Mesoporous carbon materials can be integrated into the concept of theranostics via their biocompatibility and physical properties, including light absorption in the ultraviolet and near-infrared spectrum. Their optimal structure enables the stacking of fluorescent substances, a feature successfully utilized for the detection of cancer cells via aptasensors, which are valuable in fundamental research.

Looking for Consulting & Advisory Projects