PCB Design Software Powering the Next Tech Wave

Clear insight into competitor positioning and market share.

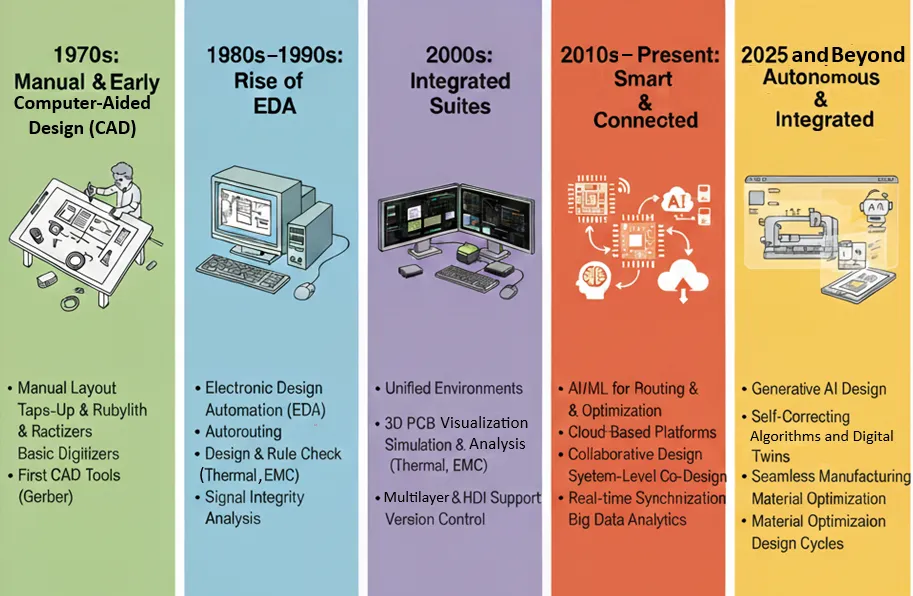

Printed circuit board (PCB) design software is a specialized tool used to automate circuit board design processes such as schematic creation, PCB layout design, 3D visualization, trace routing and component footprint creation. It enables engineers and designers to simulate their designs and validate functionality before production.

Electronics are advancing rapidly, with increasing complexity and compliance demand each year. Compliance with standards like RoHS, IPC, JEDEC and IEC is essential for meeting safety and environmental regulations. The rise of IoT, 5G, EVs and consumer electronics requires high component density, a fast time to market, and reduced defects. Additionally, modern PCB design must account for miniaturization, reliability considerations and thermal and EMC constraints to ensure optimal performance, which drives engineers to use more precise and capable tools.

Source: BCC Research

Key Industry Trends

- Advances in Electronics and Semiconductors: The demand for PCB design software is rising due to advances in the electronics and semiconductor markets, especially in consumer and automotive applications. High-density circuits drive the need for advanced multilayer and flexible PCB tools.

- Rise of IoT and Smart Devices: Billions of connected IoT devices, from smart home sensors to healthcare wearables and industrial IoT systems, are driving demand for reliable PCB prototyping and optimized designs.

- Adoption of 5G and High-Speed Networks: 5G and other high-speed networks demand PCBs that support high-frequency signals, low latency and high bandwidth. These requirements necessitate specialized design and simulation capabilities.

- Advancement in Electrification and Autonomous Systems: Electric vehicles, hybrid vehicles and autonomous systems require composite power electronics, sensors and control units, leveraging advanced PCB design software. Key PCB use cases include battery management systems (BMS), onboard chargers, ADAS sensor modules, radar/LiDAR, control units and domain controllers.

- Shift to Cloud-Based and AI-Driven Tools: Cloud-based PCB design tools support real-time collaboration across globally distributed teams. Deployment of artificial intelligence/machine learning (AI/ML) is helping automate routing, error detection and design optimization.

Industry Application and Use Cases

The ways in which different sectors find PCB design software beneficial and the value it provides are explained below.

- Automotive and EV: Battery Management and Power Electronics: Complex modern PCBs for power electronics and safety-critical systems demand high reliability. Designers now use PCB tools to simulate EMI/EMC, model vibrations and optimize thermal paths and mechanical durability to ensure performance and safety.

- Consumer Electronics and Wearables: High-Density and Rigid-Flex Design: Space and weight are critical, so PCB design software must handle High-Density Interconnect (HDI) and rigid-flex layouts to fit powerful circuits into tiny, lightweight devices. These tools also enable fast prototyping and iteration, supporting the short product cycles of smartphones and smartwatches.

- Aerospace and Defense: Reliability and Regulatory Compliance: PCB design software helps meet strict reliability and regulatory standards by enabling thermal and vibration simulations, signal integrity checks and automated documentation. These tools, along with 3D visualization and MCAD-ECAD integration, ensure boards fit mechanical constraints while supporting long-life, safety-critical applications.

- Industrial Automation, IoT and 5G: High-Speed and Signal Integrity: For 5G, the PCBs in sensor, gateway devices, and base stations must support high data rates, low power consumption and long-term sustainability. Design tools help optimize layout, trace routing, thermal management and signal integrity while ensuring compliance with industry and environmental standards.

Companies with PCB Design Automation Tools

Companies with PCB Design Automation Tools

|

Company/Tool |

Key Strengths/Distinctions |

Deployment/Pricing Style |

|

Cadence Design Systems |

Strong in high-speed, high-density designs. Complex PCB/signal integrity. AI-assisted routing (Allegro X AI). Mature

ecosystem and simulation tools. |

The tool is tailored for complex,

high-speed, and high-density designs, making it ideal for industries such as

automotive, aerospace, and telecommunications. Premium Enterprise-Oriented

Licensing is typically designed for large organizations with advanced design

needs. |

|

Altium 365 |

Good balance of

usability. Schematic

creation, layout design, trace routing and component footprint creation. Strong for

mid-range electronics design. 3D

visualization. |

Altium Designer is known

for its user-friendly interface, seamless integration with Altium 365 for

cloud-based collaboration and dedicated support for component management and

design reuse. It is particularly favored by mid-sized teams and startups for

its balance of power and usability. |

|

Siemens EDA (Mentor,

etc.) |

Extraordinarily

strong in enterprise. Industrial

automation. Integration

with PLM/ERP. Simulation and

verification (Thermal and EMC). |

Siemens EDA provides

comprehensive solutions like Xpedition and PADS, offering robust capabilities

in PCB design, simulation, and manufacturing integration. Enterprise-grade

pricing is primarily adopted by large corporations due to cost and

scalability. |

|

Autodesk/Fusion

360/Eagle |

More accessible

tools/cloud features/good for startups/small-medium businesses/easier entry. Validate

circuits virtually, cutting down costly prototyping. Automatic

updates keep every design stage aligned. Smart error

checking. Access

footprints, 3D models and parameters. Ensure

mechanical fit and manufacturability before production. |

Provides schematic

capture, PCB layout, and routing capabilities, making it suitable for

startups and small to medium-sized businesses. |

|

KiCad (open source) |

Offers schematic capture, PCB layout, SPICE simulation, 3D

rendering, BOM generation and Gerber in one suite. IPC API for plugins, scriptable workflows and community-driven

add-ons. Advanced capabilities in 9.0 Thousands of prebuilt symbols, footprints and 3D models

included. |

KiCad is a free,

open-source PCB design tool that offers advanced features like 3D

visualization and a push-and-shove router. It is ideal for hobbyists,

educators and small projects, providing a robust alternative without

licensing costs. |

Outlook

Modern PCB design software is evolving with AI-driven layout and generative routing, reducing manual work and enabling greater optimization. Cloud-native platforms support real-time collaboration, version control and remote browser-based editing for distributed teams. Integrating real-time thermal simulation helps detect issues early in the design cycle. For small and medium-sized businesses, the industry is moving toward subscription-based SaaS models, making advanced tools more accessible. There is also a growing focus on sustainability, with optimized designs and reduced material waste to support environmentally friendly manufacturing practices. Collectively, these trends are anticipated to enhance efficiency, flexibility and sustainability in PCB development.

Strategic Takeaways/Recommendations

Software vendors should focus on building features like AI-assisted routing, real-time simulation, automatic compliance checks and cloud-based collaboration tools. They should also offer flexible pricing models such as subscriptions and modular plans, catering to the needs of both large enterprises and smaller companies. This creates an opportunity to target businesses of all sizes, allowing them to choose solutions that match their specific requirements.

OEMs/hardware manufacturers should invest in upgrading design skill teams to use advanced tools. Adopting PCB software, integrated with PLM/ERP systems, enables manufacturers to receive feedback from production earlier, reducing iteration time. Choosing a platform that ensures regulatory compliance and supports reliability testing early in the design phase further improves product quality and time to market.

Looking for Consulting & Advisory Projects