Soft Grippers: The Gentle Revolution in Robotic Manipulation

In-depth market intelligence to support growth and planning.

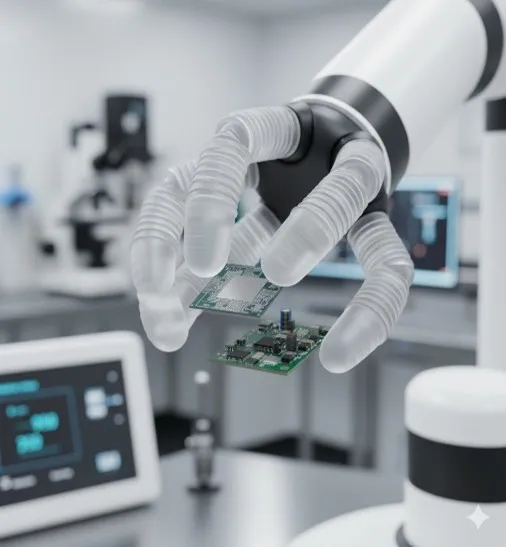

With the changing face of robotics, the most exciting recent innovation has been the creation of soft grippers. In contrast to traditional rigid robotic claws or hands, soft grippers are constructed from compliant, deformable materials such as elastomers, polymers, fabrics, or gels. Thanks to their unique geometry, these can easily bend, flex and wrap around the objects they grasp, making them particularly well-adapted for the manipulation of delicate, irregularly shaped, or fragile objects.

The driving force behind soft grippers is usually biologics. Octopus arms, starfish arms and the human hand illustrate how distributed pressure and flexibility can attain secure, variable gripping without harming the target. The application of these principles to robotics has led to grippers capable of delicately holding a strawberry, a vial of medicine, or even a slippery sea creature, an activity that has been hard or impossible for traditional rigid robotic systems.

This innovation is more than just an engineering novelty; it meets real-world needs. As food processing, agriculture, healthcare and logistics industries demand more automation, they encounter a critical challenge: traditional robots have a hard time manipulating objects of different sizes, softness, and fragility. A stiff steel gripper is great for picking up automobile components on an assembly line, but it will crush a piece of fruit or break sensitive laboratory equipment. Soft grippers, on the other hand, offer compliance and flexibility without the need for careful programming or tightly controlled environments. Outside of industry, scientific and expeditionary missions are also benefiting from soft grippers.

What Is a Soft Gripper?

Soft grippers differ from traditional rigid grippers in that they use compliance and flexibility instead of mechanical accuracy and predefined grasp points. The biggest difference lies in the number of actuation mechanisms employed to move, ranging from pneumatics to hydraulics, shape-memory alloys, dielectric elastomers, cable-driven systems, and even granular jamming methods. Each has unique trade-offs in terms of speed, force and control. Presently, new designs increasingly focus on multifunctionality, where one gripper has variable-stiffness mechanisms and can thus switch from the light grasp of a berry to the tight grasp of a glass bottle.

Further, with sensors such as strain gauges, tactile skins and pressure arrays embedded within soft grippers, they evolve from passive tools to active, smart manipulators that can sense slip, monitor grip force and adjust in real time. This movement emphasizes that soft grippers are not merely compliant substitutes for hard claws anymore; they are fast-emerging platform technologies at the confluence of materials science, robotics and AI, tailored to be multifaceted across multiple industries.

Currently, soft grippers occupy the confluence of materials science, robotics and AI control, and they are a primary frontier of automation. Since 2024, there has been a significant improvement in their durability, integration of sensing and variable-stiffness actuation, making them potentially more suitable for broad commercial applications. As standards improve and costs reduce, soft grippers are on the verge of moving from being specialized laboratory tools to becoming an industrial mainstream solution.

From Fragile Goods to Future Tech: Why Soft Grippers Matter?

Multiple technological advances and market forces are fueling the growth of soft grippers. Improvements in materials science, such as elastomers, magnetorheological composites and 3D printing of soft structures, have enabled grippers that are both affordable and dependable. Agriculture, food processing, healthcare and electronics are among the industries increasingly seeking automation solutions that can handle fragile and irregular products without damage. Soft grippers are uniquely suited to address this challenge. Government programs like the National Science Foundation (NSF), Future Manufacturing Program, National Institute of Standards and Technology (NIST), National Oceanic and Atmospheric Administration (NOAA), and ocean exploration initiatives have also accelerated development.

The 2024 Soft Robotics Report by NIST highlighted safe, cooperative systems, while NOAA and the National Aeronautics and Space Administration (NASA) have applied soft grippers for tasks such as coral sampling to extraterrestrial robotics. Furthermore, improved sensing technology and AI-driven control enable soft grippers to sense slip, control pressure and function in less structured environments, thus being more pragmatic for real-world applications.

Integration with Collaborative Robots (Cobots): Soft grippers are the best-suited end-effectors for cobots, since their softness inherently promotes human-robot safety by reducing the chance of injury while co-working. This fits into the emerging trend that human-safe automation is driving market penetration at a faster pace.

Industry 4.0 and Smart Manufacturing: The transition toward Industry 4.0 concepts, which focus on interconnected smart factories and variable production, fuels the need for adaptive devices such as soft grippers. They play a crucial role in applications that involve versatility and real-time adaptability, including automated warehousing, logistics and e-commerce packaging handling different types of packages.

Increasing Miniaturization in Electronics: The ongoing trend of miniaturization, especially in the semiconductor and electronics sectors, demands highly accurate but delicate handling. Soft grippers are well-designed for the assembly and manipulation of fragile micro-components without causing any damage.

Challenges on the Road to Adoption

While the soft gripper boasts much promise, many challenges continue to delay its widespread adoption. The foremost technical barrier is that its reproduction is difficult because the flexible deformation of soft matter is inherently difficult to model, predict and standardize. This inconsistency sometimes leads to performance discrepancies from gripper to gripper, thereby creating an even more challenging reliance for large-scale industries. Durability stands as another challenge: rubber-like materials, pneumatic membranes and other compliant substances usually erode, wear, or leak in harsh industrial applications, such as on a food processing or packaging line.

Force control and payload capacity in soft grippers still lag behind rigid or hybrid designs, limiting their effectiveness in heavy-duty applications or tasks that demand high precision. Although research toward variable-stiffness mechanisms is beginning to address this problem, the technology is not advanced enough to make a complete transition to alternative traditional ones. Finally, the lack of well-proscribed regulatory and certification frameworks for soft robotics slows the adoption of the technology in areas such as healthcare, pharmaceuticals and food handling, where conformity is a must.

Recent Developments

In recent years, soft grippers have progressed very quickly from lab research into practical, real-world applications. Since 2024, specifically, technology has witnessed advances not just in actuator design and materials but also in integration with sensing, AI and standards frameworks. Government organizations like NIST, NASA and NOAA have progressively funded these developments, while scholarly surveys and technical breakthroughs have started to integrate knowledge and propel the technology toward commercialization. These advancements reflect how soft grippers are becoming a mature suite of tools for applications from manufacturing and medicine to space travel and oceanography.

Slip Detection in Robotic Grippers Using Stretchable, Soft Multi-Axial (2025): It describes a soft multi-axial tactile sensor system embedded in a gripper, enabling slip detection and force measurement in a deformable context. The sensor will have enhanced adaptability, thus mimicking the skin's flexibility like human touch.

Smart Gripper with Soft Fingers and Integrated Force Sensors for Adaptive Robotic Tasks (2025): It describes a tendon-driven soft robotic gripper with integrated sensing fingertips, i.e., the soft fingers themselves include force/position sensors.

NIST FY24 Soft Robotics Report (2024): As a comprehensive government review, it surveyed academic and industrial challenges in soft robotics, focusing on metrology, reproducibility and materials, characterizing the essence of the new standards that need to be established to expedite commercialization.

NOAA/Ocean Exploration projects (2024): NOAA-sponsored efforts have employed hybrid soft robotic manipulators in the selective sampling of sensitive benthic sites, demonstrating how soft grippers have enabled science missions that would have damaged the habitat if executed with rigid tooling.

NASA interest and outreach (2024): NASA produced public outreach material on research into soft robotics at the Langley Research Center, investigating how soft-manipulator technologies might play a role in future lunar surface activities.

Peer-reviewed survey and reviews (2024): Several open-access and academic reviews that appeared in 2024 systematize almost a decade of soft gripper work, reviewing families of actuation, sensing trends and application domains.

Technical innovation in variable stiffness and multifunction actuators (2024): New actuator concepts (e.g., the MASH actuator) allow a singular soft gripper to change its stiffness and adaptively adjust its effective gripping range.

Future Outlook: Where to Invest or Expand

Investments in the soft gripper market are best directed toward improving both performance and reliability while expanding real-world applications. A key focus is materials and durability R&D, where new elastomers, coatings and composites can extend gripper lifetimes, supported by standardized testing frameworks from organizations like NIST. Another area of growth lies in modular and hybrid designs, which combine soft contact surfaces with rigid cores or variable-stiffness systems to balance flexibility with strength. To enhance adaptability, companies are increasingly turning to sensing and AI integration, embedding tactile skins and deploying machine learning algorithms for slip detection and more reliable grasping.

At the same time, establishing standards and benchmarks through participation in metrology consortia and reproducibility initiatives is crucial to scaling adoption across industries. Finally, mission-driven pilots in collaboration with agencies such as NOAA, NASA and agricultural research bodies present valuable opportunities to demonstrate soft grippers in specialized, high-impact environments and validate their performance in real-world conditions.

Looking for Consulting & Advisory Projects